Contact us

E-mail: info@hktpump.com

Phone: +86-13323110006

WhatsApp: +8613323110006

Yigu Information Industry Park, Xinzhaidian, Zhao County, Shijiazhuang, Hebei Province, China

SXH-HH slurry pump

- 产品描述

-

AH type slurry pump

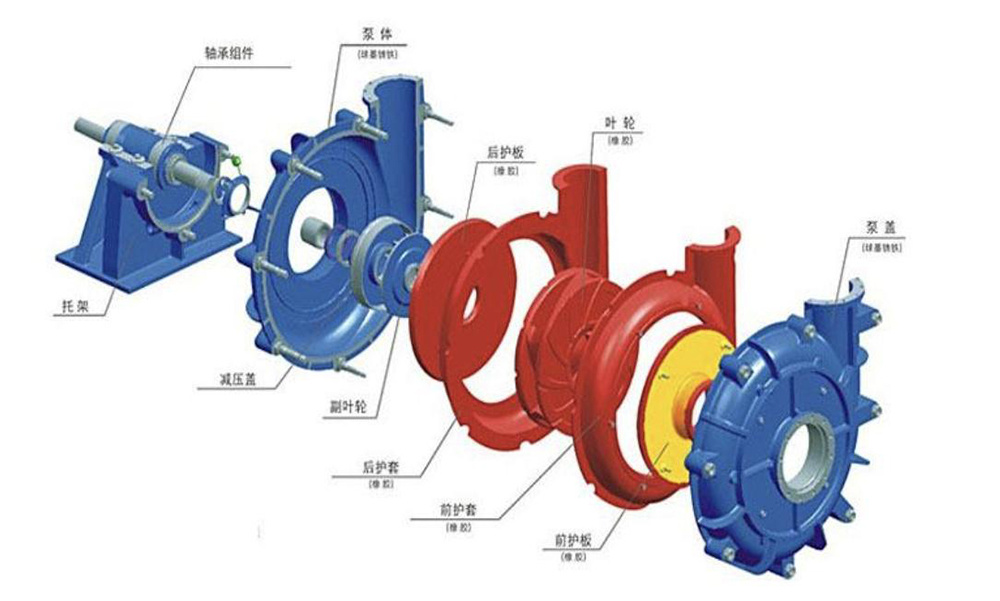

AH horizontal centrifugal slurry pump. Suitable for metallurgical, mining, coal, power, building materials and other industrial sectors for transporting highly abrasive, high-concentration slurry. This type of pump can also be used in multi-stage series. The pump body of M, AH, and HH type pumps has replaceable wear-resistant metal or rubber linings, and the impeller uses wear-resistant metal or rubber materials.

Introduction to AH type slurry pump

Pump body, pump cover and flow parts: This series of pumps are horizontal, vertical medium form, double pump shell structure slurry pumps. The pump body and pump cover have replaceable metal linings, the lining material is high-chromium wear-resistant alloy material, and the lining can be used until it is worn through, extending the maintenance cycle and reducing operating costs. The pump outlet direction can be rotated and installed at 8 angles.

Bearing assembly: The pump bearing assembly adopts a cylindrical structure, which is convenient for adjusting the clearance between the impeller and the front guard plate, and can be removed as a whole during maintenance. The bearings are lubricated with grease.

Shaft seal (seal): The pump shaft seal types include packing seal, auxiliary impeller seal, and mechanical seal.

Transmission method: There are V-belt drive, elastic coupling drive, gear reducer drive, fluid coupling drive, frequency converter drive, and thyristor speed regulation, etc. Among them, V-belt drive has CL, CV, CR, ZL, ZV, and ZR drives.

Overall performance: The pump has a wide performance range, good cavitation performance, and high efficiency. Multi-stage series technology can be used to meet long-distance transportation. The flow parts have a variety of metals to choose from, and the depth is increased. Using a variety of speeds and various transformation methods, the pump operates in mining and industrial areas. Long service life, high operating efficiency, and ability to meet various harsh transportation conditions.

Working principle of slurry pump

First, let's talk about the relationship between centrifugal pumps and slurry pumps, and then the principle of slurry pumps will naturally become clear. The centrifugal concept is from the original pump. There are many types of pumps, and according to different angles, they can be divided into dozens of categories. Centrifugal pumps are classified according to the working principle of the pump, which is the process of increasing the pressure of the transported medium through centrifugal force. Other common types include screw principle, plunger principle, etc., which can be divided into pumps different from the centrifugal principle. After talking about the concept of centrifugal pumps, let's talk about slurry pumps. Slurry pumps are classified from another angle, that is, classified from the transported medium. As the name suggests, slurry pumps transport a mixture of solid particles containing slag and water. But in terms of principle, slurry pumps belong to a kind of centrifugal pump. In this way, these two concepts are explained clearly.

The main working parts of a centrifugal pump are the impeller and the casing. The impeller in the casing is located on the shaft and connected to the prime mover to form an integral unit. When the prime mover drives the impeller to rotate, the blades in the impeller force the fluid to rotate, that is, the blades do work on the fluid along its direction of motion, thereby forcing the pressure potential energy and kinetic energy of the fluid to increase. At the same time, under the action of inertial force, the fluid flows from the center to the edge of the impeller, and flows out of the impeller at a high speed, enters the discharge chamber, and then is discharged through the diffuser, this process is called the pressurization process. At the same time, because the fluid at the center of the impeller flows towards the edge, a low-pressure area is formed at the center of the impeller. When it has sufficient vacuum, under the action of the pressure at the suction end (generally atmospheric pressure), the fluid enters the impeller through the suction chamber, this process is called the suction process. Due to the continuous rotation of the impeller, the fluid is continuously discharged and sucked in, forming continuous operation.

The working process of a centrifugal pump (including a slurry pump) is actually a process of energy transfer and conversion. It transfers the high-speed rotating mechanical energy of the motor through the pump blades and converts it into the pressure energy and kinetic energy of the pumped fluid.

Uses of AH type, M type and HH type fractional slurry pumps

Slurry pumps are widely used in mining, power, metallurgy, coal, and environmental protection industries to transport slurries containing abrasive solid particles. Such as metallurgical beneficiation plant pulp transportation, thermal power plant hydraulic ash removal, coal washing plant coal slurry and dense medium transportation, dredging rivers, river dredging, etc. In the chemical industry, some slurries containing crystals and corrosives can also be transported.

First, in the beneficiation plant, about 80% are used in the mining industry's beneficiation plant. Due to the harsh operating conditions of the initial ore selection, the service life of slurry pumps is generally short in this section. Of course, the abrasiveness of different ores is also different. For example, in the fine ore transportation section, the abrasiveness is relatively reduced, and the overall service life of the pump is longer. Therefore, when users often ask suppliers about the service life of their products during the procurement process, strictly speaking, any manufacturer will not promise a precise service life cycle without any basis, because the service life of the flow parts (wear-resistant and corrosion-resistant parts) depends on various different factors, and the diversity and complexity of operating conditions lead to differences in the service life of materials of the same quality. However, in the early stage of selection, manufacturers with strong capabilities can make reasonable operating condition selection and design for them.

Secondly, in the power industry, it is mainly thermal power plants. Currently, China's power plants mainly use thermal power generation and hydropower generation. In thermal power plants, due to the use of a large amount of coal-fired power generation, the slag or ash after coal combustion needs to be removed, and the slurry pump is used in the role of ash removal, and the slag is transported to the ash dump after mixing a certain amount of water through the slurry pump, so sometimes the slurry pump is also called the ash pump in the power plant.

Thirdly, in the coal washing industry, due to different operating conditions, larger coal pieces and gangue are easy to block, and the design requirements for slurry pumps are very high. A coal washing plant under Huaibei Mining Bureau adopted a specially designed slurry pump in 2005 to replace the slurry pump originally imported from Australia. It has been operating normally, transporting larger coal pieces and gangue without blockage, and its wear and tear life has exceeded that of imported pumps from abroad.

In the field of seawater sand selection, slurry pumps are also gradually being recognized by customers. However, in seawater sand selection and river dredging, slurry pumps are more easily referred to as sand pumps or dredging pumps. Despite the different names, from the structural characteristics and pump performance principles, they can all be generally called slurry pumps. Therefore, in seawater sand selection, we often call them sand pumps, while in river dredging, they are customarily called dredging pumps.

Although slurry pumps have a wide range of uses, correct application is crucial. Due to limitations in the name itself, some people outside the industry misunderstand slurry pumps. In fact, mud pumps, impurity pumps, dredging pumps, and dredging pumps all fall within the scope of slurry pump applications. During the application of slurry pumps, it is essential to pay attention to reasonable design, correct calculations, and appropriate selection. These points are very important.

AH Slurry Pump Performance Parameters Table

Model Power

P(KW)Clear Water Performance Flow Rate Q

(m³/h)Head H

(m)Speed

n(r/min)Maximum Efficiency

η%Net Positive Suction Head

NPSH(m)Weight

(Kg)1.5/1B-AH 2.2-15 3.6-20 5-68 1200-3800 40 2-4 91 2/1.5B-AH 2.2-15 7-48 7-62 1200-3200 45 3.5-8 118 3/2C-AH 4-30 21-86 12-65 1300-2700 55 4-6 191 4/3C-AH 5.5-30 50-150 9-45 1000-2000 71 4-6 263 4/3D-AH 7.5-60 68-160 10-52 1000-2200 71 4-6 363 6/4D-AH 15-60 72-360 12-56 800-1550 65 5-8 626 6/4E-AH 22-120 93-385 12-63 800-1600 65 5-8 728 8/6E-AH 18.5-120, 360-820 10-61 500-1100 72 2-9 1473 8/6R-AH 110-300 360-820 10-61 500-1140 72 2-9 1836 10/8ST-AH 45-560 630-1300 11-60 400-850 71 4-10 3750 12/10ST-AH 55-560 800-1900 7-58 350-730 82 6 4318 14/12ST-AH 75-560 1200-2600 13-60 300-600 77 3-10 4609 16/14TU-AH 160-1200 1368-3000 11-60 250-550 79 4-10 10000 AH Type Slurry Pump Structure Diagram

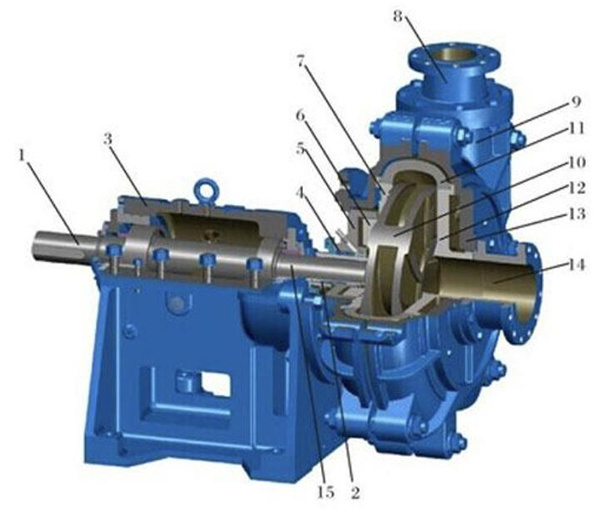

1. Shaft 2. Shaft Seal 3. Support Component 4. Packing 5. Packing Box 6. Secondary Impeller 7. Rear Casing 8. Discharge Pipe 9. Pump Casing 10. Impeller 11. Liner 12. Front Casing 13. Pump Cover 14. Suction Port 15. Sleeve On-site Photos

Product System

The company's industrial pump production base focuses on meeting the needs of various industrial scenarios. We are committed to creating products such as slurry pumps, desulfurization pumps, dredging pumps, submersible pumps, and chemical pumps. From the demand for high wear-resistant slurry pumps in large-scale mining, to the dependence on high-efficiency desulfurization pumps in power plant desulfurization, to the strict requirements for high corrosion-resistant chemical pumps in fine chemical processes, we can provide high-performance products that are suitable for all. These pumps are widely used in industries such as mining, power plant desulfurization, river sand mining, metallurgy and steel, chemical industry, etc.

The valve production base covers various categories such as ball valves, gate valves, butterfly valves, etc. With excellent quality and reliable performance, it is widely used in the fields of oil and gas transmission pipelines, urban water supply and drainage systems, etc., to ensure the safe and stable operation of various fluid transmission systems.

Contact Us

Keywords: