Contact us

E-mail: info@hktpump.com

Phone: +86-13323110006

WhatsApp: +8613323110006

Yigu Information Industry Park, Xinzhaidian, Zhao County, Shijiazhuang, Hebei Province, China

DT desulfurization pump

- 产品描述

-

Product Introduction

The DT desulfurization pump is a single-stage, single-suction, horizontal centrifugal pump, mainly used as an absorption tower circulating pump. It features a wide flow range, high efficiency and energy saving, simple structure, and convenient maintenance. It is an ideal product for power plant desulfurization and slag removal.

Material: Wear-resistant and corrosion-resistant A49 material.Model Significance

For example: 200DT-45B

200: Outlet diameter is 200mm

DT: Desulfurization pump

45: Impeller diameter 45cm

B: Number of impeller blades; A is 5 blades, B is 4 blades, C is 3 blades

Desulfurization Pump Features

The DT series desulfurization pump is a single-stage, single-suction, horizontal centrifugal pump, mainly used as an absorption tower circulating pump in wet FGD systems. It features a wide flow range, high efficiency and energy saving, simple structure, and convenient maintenance. This series of pumps is equipped with a compact X-type bracket, which can greatly save space. At the same time, our factory has developed a variety of new materials for desulfurization system pumps to meet the needs of various operating conditions in power plants.

Desulfurization Pump Structure

In the rubber pump structure: The impeller, suction cover, and front guard plate are made of special wear-resistant materials. The front casing, rear casing, and rear guard plate are made of natural rubber, which has excellent natural wear and corrosion resistance, is lightweight, and relatively low in cost. In the metal structure: The impeller, casing, front guard plate, and rear guard plate are made of special wear-resistant and corrosion-resistant materials. The suction cover is cast iron with rubber lining.

Sealing Type: The mechanical seal uses a cartridge-type seal specifically designed for desulfurization processes, ensuring reliable operation.

Transmission Method: V-belt drive, elastic coupling drive, gear reducer drive, fluid coupling drive, variable frequency drive, and thyristor speed regulation, etc. Multiple speeds and various variations are used, allowing the pump to operate under optimal conditions, ensuring a long service life, high operating efficiency, and the ability to meet a variety of harsh conveying conditions.

Application Range of Desulfurization Pumps

A desulfurization pump is a mechanical pump with corrosion resistance, mainly used for conveying corrosive liquids. It is a widely used type of general-purpose equipment pump, with advantages such as good sealing performance, long service life, and wide applicability. Its corrosion resistance, wear resistance, and non-deformability allow it to be used for conveying corrosive clear liquids in industries such as sulfuric acid and phosphate fertilizer, non-ferrous metal smelting, chemical engineering and chemical, and chlor-alkali industries. The application range of desulfurization pumps is extremely wide. Specifically, desulfurization pumps are mainly used in the following aspects:

1. Sulfuric Acid and Phosphate Fertilizer Industry: Mainly used for conveying dilute acid, mother liquor, wastewater, seawater, silica-containing liquids, and phosphoric acid slurry.

2. Non-ferrous Metal Smelting Industry: Mainly applicable for conveying various acid solutions, corrosive ore pulps, electrolyte pulps, and wastewater in the hydrometallurgy of lead, zinc, gold, silver, copper, manganese, cobalt, and rare earths.

3. Chemical and Other Enterprises: Mainly used for conveying sulfuric acid, hydrochloric acid, alkaline, and oil clear liquids or slurries, as well as various dyes and pigments in titanium and iron production.

4. Chlor-alkali Industry: Mainly used for conveying hydrochloric acid, liquid alkali, and electrolytes.

5. Water Treatment Industry: Mainly used for conveying pure water, ultrapure water, and various wastewaters.

6. Iron and Steel Enterprises: Mainly used for conveying sulfuric acid, hydrochloric acid, and wastewater with impurities in pickling systems.

7. Coal Industry and Coal Chemical Industry: Mainly used for conveying corrosive liquids and coal slurry, as well as auxiliary pumps for coal washing and selection wastewater.

Desulfurization pumps use high-strength, wear-resistant materials for flow components, suitable for conveying strongly abrasive, high-concentration, and large-particle slurries. They can be used in multi-stage series within the pump's larger operating pressure range.

Depending on the medium being pumped, desulfurization pumps have interchangeable flow components of various materials, suitable for conveying abrasive or corrosive, large-particle or fine-particle slurries.

Performance Parameter Table

Model Speed n

r/min

Flow Rate Q

m³/hHead H

mShaft Power Pa

KWEfficiency η

%Required Net Positive Suction Head (NPSHr)

mMotor Power/Voltage

KW/V800DT-A90 590 6200 28.7 553.2 87.6 2.7 710/6000 8800 26.1 700.4 89.3 3.5 900/6000 9700 23.5 715.2 86.8 3.9 900/6000 490 5170 20.0 321.5 87.6 2.0 400/6000 7338 18.1 405.0 89.3 2.5 500/6000 8089 16.3 413.7 86.8 2.9 560/6000 700DT-A84 590 4250 24.5 326.3 86.9 2.8 500/6000 6300 22.3 430.9 88.8 3.5 560/6000 7360 20.1 467.4 86.2 4.0 630/6000 490 3545 17.0 188.9 86.9 2.0 250/6000 5255 15.5 250.0 88.8 2.6 315/6000 6140 14.0 271.6 86.2 3.0 355/6000 600DT-A82 590 3300 27.8 343.2 72.8 3.0 500/6000 4700 24.7 358.0 88.3 3.7 500/6000 5300 21.7 362.9 86.3 4.0 500/6000 5600 20.4 368.2 84.5 4.0 500/6000 490 2718 18.9 192.2 72.8 2.2 280/6000 3871 16.8 200.6 88.3 2.8 280/6000 4368 14.7 202.5 86.3 3.0 280/6000 4612 13.8 205.1 84.5 3.0 280/6000 500DT-A85 590 2040 26.8 204.5 72.8 4.1 250/6000 3400 24.4 266.7 84.7 355/6000 4080 22.4 305.2 80.1 400/6000 490 1702 18.6 118.4 72.8 3.1 220/6000 2836 17.0 155.0 84.7 220/6000 3403 15.3 177.0 80.1 220/6000 350DT-A78 740 1332 51.1 289.6 64.0 6.5 355/6000 2430 44.5 377.7 78.0 500/6000 2865 39.6 408.7 75.6 500/6000 590 1062 32.5 146.9 64.0 3.5 185/6000 1938 28.3 191.5 78.0 250/6000 2284 25.2 207.3 75.6 280/6000 300DT-A60 980 1170 63.1 235.6 71.8 8.4 315/6000 1779 47.1 281.4 81.1 355/6000 2403 36.1 313.3 75.4 400/6000 740 878 29.9 99.6 71.8 4.3 132/380 1335 26.5 118.8 81.1 160/380 1803 20.3 132.2 75.4 160/380 200DT-45B 990 279 31.0 37.4 62.9 3.3 55/380 557 26.1 49.0 80.8 75/380 645 23.3 52.6 77.8 75/380 730 206 16.9 15.1 62.9 2.0 22/380 410 14.2 19.6 80.8 30/380 475 12.7 21.1 77.8 30/380 150DT-55B 990 280 53.7 64.8 63.2 3.7 90/380 517 48.0 88.3 76.5 110/380 630 45.9 100.8 78.1 132/380 740 209 30.0 27.0 63.2 2.3 37/380 387 26.8 36.9 76.5 55/380 471 25.7 42.2 78.1 55/380 150DT-50 980 123 44.6 27.6 54.1 3.5 37/380 221 40.1 36.9 65.4 55/380 279 37.2 43.4 65.2 55/380 740 92 24.7 11.4 54.1 2.1 18.5/380 165 22.3 15.3 65.4 22/380 208 20.6 17.9 65.2 30/380 150DT-40 1480 260 61.2 68.8 63.0 6.5 90/380 440 53.8 88.2 73.1 110/380 503 50.7 95.4 72.8 132/380 980 171 26.5 19.6 63.0 2.6 30/380 289 23.3 25.1 73.1 37/380 331 21.9 27.1 72.8 37/380 100DT-45 1480 88 76.4 43.6 42.0 6.0 55/380 166 65.2 56.9 51.8 75/380 219 54.3 66.5 48.7 90/380 970 57 32.8 12.1 42.0 2.4 18.5/380 109 28.0 16.0 51.8 22/380 144 23.3 18.8 48.7 30/380 100DT-40B 1480 129 61.0 37.7 56.9 3.5 55/380 219 56.1 48.7 68.7 75/380 268 53.6 55.6 70.4 75/380 970 85 26.2 10.7 56.9 1.7 15/380 144 24.1 13.8 68.7 22/380 176 23.0 15.7 70.4 22/380 100DT-35 1480 163 45.9 33.5 60.9 4.1 45/380 278 41.5 43.7 71.9 55/380 323 39.2 47.1 73.2 75/380 970 107 19.7 9.4 60.9 1.9 15/380 182 17.8 12.3 71.9 18.5/380 212 16.8 13.3 73.2 18.5/380 80DT-36 1480 86 47.1 23.3 47.4 3.2 30/380 151 42.0 28.5 60.7 37/380 167 39.9 29.3 62.0 37/380 970 56 20.2 6.5 47.4 1.5 11/380 99 18.0 8.0 60.7 15/380 109 17.1 8.2 62.0 15/380 65DT-40 1480 71 63.2 26.2 46.7 4.5 37/380 141 57.5 35.6 62.1 45/380 159 54.6 36.1 62.1 55/380 970 47 27.1 7.4 46.7 2.1 11/380 92 24.7 10.0 62.1 15/380 104 23.5 10.7 62.1 15/380 65DT-30 1480 44 35.6 9.1 46.7 4.6 15/380 79 32.6 12.8 54.6 18.5/380 99 30.7 15.4 53.8 22/380 960 29 15.2 2.6 46.7 2.2 5.5/380 51 13.9 3.5 54.6 5.5/380 64 13.1 4.2 53.8 7.5/380 50DT-40D 1480 33 51.7 13.1 35.4 2.5 18.5/380 68 43.4 17.8 45.4 30/380 76 40.8 18.9 44.7 30/380 970 22 22.5 3.8 35.4 1.2 5.5/380 45 18.9 5.1 45.1 7.5/380 50 17.7 5.4 44.7 11/380 50DT-30 1480 34 36.3 7.8 43.1 1.6 11/380 55 31.9 9.9 48.5 15/380 78 26.4 12.4 45.4 18.5/380 960 22 15.7 2.2 43.1 0.8 4/380 36 13.8 2.8 48.5 4/380 51 11.4 3.5 45.4 5.5/380 40DT-25 [a] 2950 35.5 88.6 20.7 41.3 - 30/380 58.5 73.5 27.7 42.5 37/380 74.7 60.8 31.2 39.6 45/380 1440 17.3 21.1 2.4 41.3 2.6 4/380 28.7 17.5 3.2 42.5 5.5/380 36.5 14.5 3.6 39.6 5.5/380 40DT-20B 2930 16.6 57.5 6.4 40.9 3.5 11/380 33.3 49.9 8.5 53.0 15/380 37.1 47.1 9.2 52.0 15/380 1430 8.1 13.7 0.7 40.9 0.9 1.5/380 16.3 11.9 1.0 53.0 2.2/380 18.1 11.2 1.1 52.0 2.2/380 40DT-19 2930 16.3 57.1 6.5 39.2 4.9 11/380 30.0 54.9 8.1 55.4 15/380 34.9 53.7 8.7 58.8 15/380 1400 7.8 13.0 0.7 39.2 1.2 1.5/380 14.3 12.5 0.9 55.4 1.5/380 16.7 12.3 1.0 58.8 2.2/380 40DT-17 2900 9.4 44.6 3.4 33.2 4.5 5.5/380 17.9 42.7 4.2 49.5 7.5/380 23.4 39.3 4.8 52.4 7.5/380 1400 4.6 10.4 0.4 33.2 2.5 0.75/380 8.6 10.0 0.5 49.5 1.1/380 11.3 9.2 0.5 52.4 1.1/380 25DT-25 1440 9.6 21.6 1.7 33.2 7.1 3/380 17.8 16.6 2.1 38.0 4/380 19.9 13.9 2.1 33.8 4/380 910 6.0 8.6 0.4 33.2 3.3 0.75/380 11.2 6.6 0.5 38.0 1.1/380 12.5 5.5 0.6 33.8 1.1/380 25DT-15 2900 9.2 34.4 2.6 32.7 5.3 5.5/380 17.1 29.5 3.3 41.8 5.5/380 19.3 27.1 3.5 40.8 5.5/380 1390 4.4 7.9 0.3 32.7 1.3 0.55/380 8.2 6.8 0.4 41.8 0.75/380 6.3 6.2 0.4 40.8 0.75/380 Structural Description

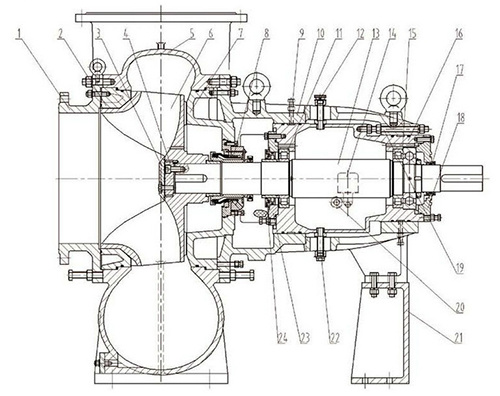

Structure of pumps with a diameter of 400 mm or more: The pump body is connected to the suspension body. The medium end uses a single row of cylindrical roller bearings to bear radial force, while the drive end uses a single row of cylindrical roller bearings and a single row of four-point contact ball bearings to bear radial and axial forces. The impeller is locked by the impeller cover structure, and the clearance between the impeller and the wear plate is adjusted by an axial adjustment device.

1. Front Pump Cover 13. Shaft 2. Wear Plate 14. Oil Level Gauge Component 3. Impeller Cover 15. Cylindrical Roller Bearings and Four-Point Contact Ball Bearings 4. Shaft Cap Gasket 16. Bearing Housing 5. Pump Body 17. Bearing Isolator 6. Impeller 18. Rear Bearing Cover 7. Rear Pump Cover 19. Adjusting Bolt 8. Mechanical Seal Component 20. Oil Level Indicator 9. Clamping Bolt 21. Foot 10. Suspension Body 22. Screw Plug 11. Cylindrical Roller Bearing 23. Front Bearing Cover 12. Vent Cover 24. Bearing Isolator

Product System

The company's industrial pump production base focuses on meeting the needs of various industrial scenarios. We are committed to creating products such as slurry pumps, desulfurization pumps, dredging pumps, submersible pumps, and chemical pumps. From the demand for high wear-resistant slurry pumps in large-scale mining, to the dependence on high-efficiency desulfurization pumps in power plant desulfurization, to the strict requirements for high corrosion-resistant chemical pumps in fine chemical processes, we can provide high-performance products that are suitable for all. These pumps are widely used in industries such as mining, power plant desulfurization, river sand mining, metallurgy and steel, chemical industry, etc.

The valve production base covers various categories such as ball valves, gate valves, butterfly valves, etc. With excellent quality and reliable performance, it is widely used in the fields of oil and gas transmission pipelines, urban water supply and drainage systems, etc., to ensure the safe and stable operation of various fluid transmission systems.

Contact Us

Keywords: