Contact us

E-mail: info@hktpump.com

Phone: +86-13323110006

WhatsApp: +8613323110006

Yigu Information Industry Park, Xinzhaidian, Zhao County, Shijiazhuang, Hebei Province, China

Submersible slurry pump

- 产品描述

-

Product Introduction and Description

The ZJQ and NSQ submersible slurry pumps and sand suction pumps are hydraulic machines where the motor and pump are coaxial and submerged in the medium. The pump's flow components are made of high-strength wear-resistant alloys, wear-resistant cast iron, and cast steel. The material of the flow components is determined based on the liquid discharged by the customer's operation. The pump has a large flow passage and is suitable for conveying mud, slurry, coal slurry, sand and gravel, etc., containing relatively large solid particles. It can also be used for river dredging, sewage, manure, slurry feed suction, irrigation, and can also be used in municipal, chemical dyeing, pharmaceutical, shipbuilding, food, etc., as well as sucking high-viscosity liquids, sewage, pasty substances, etc. It is an important piece of equipment that cannot be replaced by submersible sewage pumps.

This series of products adopts advanced technologies from home and abroad. In addition to the main impeller, a stirring impeller is added to the bottom of the water pump, which can spray the deposited sludge into turbulence, allowing the pump to achieve high-concentration conveying without auxiliary devices. The unique sealing device can effectively balance the pressure inside and outside the oil chamber, maximizing the reliability of the mechanical seal. The motor adopts multiple protection measures such as overheating protection and water ingress detection protection, replacing the usability, reliability, and service life of various vertical pumps. It can operate safely and reliably under harsh working conditions for a long time.

Suitable for extracting construction sand, fine sand, sludge, tailings, mineral sands, iron sand ore, rivers, lakes, reservoirs, ports, etc., for sand dredging and dredging projects. It can also be used for clearing sediment in sedimentation tanks of steel mills, power plants, iron ore plants, oil fields, and other industrial and mining enterprises, as well as wastewater treatment plant sediments, etc.

The company is engaged in the research and development and production of hydraulic sand dredging and dredging equipment, and provides experience in corresponding vertical and horizontal dredging sand pumps for different construction environments. It has now developed submersible slurry pumps and sand suction pumps. We always adhere to people-oriented, technological innovation, continuously improve internal business management, improve product quality, and provide excellent and unique after-sales service and good corporate reputation. We constantly meet customer needs and make your business a success through our expertise – that is our eternal pursuit!

Structural Description

1. The whole machine is a dry type water pump. The motor adopts an oil chamber sealing method with an internal mechanical seal to effectively prevent high-pressure water and impurities from entering the motor cavity.

2. In addition to the main impeller, there is also a stirring impeller, which can stir the sludge sediment at the bottom of the water into turbulence before extraction.

3. The impeller and stirring impeller and other flow components use high-hardness high-strength wear-resistant alloy (C), cast iron (M), and cast steel (G). They have strong sand discharge capacity and can discharge relatively large solid particles.

4. The motor is submerged underwater, not limited by the suction head, with high suction efficiency, and more thorough dredging.

5. The overall equipment is simplified, and no auxiliary stirring device or spraying device is required, making operation simple and reducing the total investment of the unit.

6. The stirring impeller is directly close to the sedimentation surface, and the concentration is controlled by the submergence depth. In the case of a large specific gravity of the medium, auxiliary devices can be added to increase the medium concentration.

Operating Conditions

1. The power supply is a 50HZ/60HZ/380V/415V/660V/1140V three-phase AC power supply. The capacity of the distribution transformer is 2-3 times the rated capacity of the motor.

2. The medium temperature should not exceed 60, xSQ(R) type not exceeding 140, and does not contain flammable or explosive gases.

3. Maximum weight concentration of solid particles in the medium: ash is 45%, and slag is 60%.

4. For pumps with an internal self-circulating cooling system, the motor part should not be exposed to the liquid surface by more than 1/2.

5. Unit submergence depth: not more than 40 meters, the minimum submergence depth shall be based on submerging the motor.

6. The working position of the unit in the medium is vertical, and the upper part is suspended for positioning.

7. Generally, the pump must be used within the operating head range to ensure that the motor is not overloaded. If it needs to be used in the full head range, please specify it when ordering, so that the manufacturer can produce it accordingly.

Advantages

(1) Compared with general horizontal pumps, submersible slurry pumps and sand suction pumps have the following advantages:

1. Compact structure and small footprint. Because it works submerged in the liquid, it can be directly installed in the sewage sand discharge pool without the need to build a special pump room to install the pump and motor, saving a lot of land and construction costs.

2. Convenient installation and maintenance, and flexible installation.

3. Long continuous running time. Because the pump and motor are coaxial and the shaft is short and the rotating parts are light, the load (radial) on the bearings is relatively small, and the service life is much longer than that of ordinary pumps.

4. There are no cavitation damage or priming problems. The latter point, in particular, is very convenient for operators. Because of the above advantages, it has been increasingly valued and its application range has become wider, from the original use of simply conveying high-concentration sand and mud to now conveying various domestic sewage, industrial wastewater, construction site drainage, liquid feed, etc. It plays a very important role in municipal engineering, industry, hospitals, construction, hotels, water conservancy construction, and other industries.

(2) Sealing Technology

The so-called auxiliary impeller fluid dynamic seal refers to an auxiliary impeller installed behind the pump cover that rotates in the opposite direction to the main impeller. When the pump is operating, the auxiliary impeller rotates with the main shaft of the pump, and the liquid in the auxiliary impeller also rotates. The rotating liquid generates an outward centrifugal force. This centrifugal force, on the one hand, pushes against the liquid flowing to the mechanical seal, reducing the pressure at the mechanical seal. On the other hand, it prevents solid particles in the medium from entering the friction of the mechanical seal, reducing the wear of the mechanical seal wear block, and extending its service life. In addition to its sealing function, the auxiliary impeller can also reduce axial force. In this type of pump, the axial force is mainly composed of the pressure difference force of the liquid acting on the impeller and the gravity of the entire rotating part. The directions of these two forces are the same, and the resultant force is the sum of the two forces. It can be seen that, under the condition of completely identical performance parameters, the axial force of this type of pump is greater than that of a general horizontal pump, and the balancing difficulty is greater than that of a vertical pump. Therefore, in this type of pump, the bearing is prone to damage, and the reason is also largely related to the axial force. If an auxiliary impeller is installed, the direction of the pressure difference force on the auxiliary impeller is opposite to the resultant force of the above two forces, which can offset part of the axial force and extend the service life of the bearing. However, there is also a disadvantage to using an auxiliary impeller sealing system, which is that some energy is consumed on the auxiliary impeller, generally about 3%. As long as the medium is reasonably designed, this loss can be minimized.

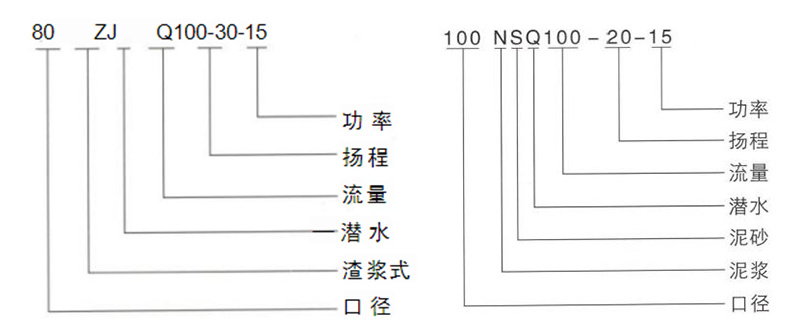

Model Significance

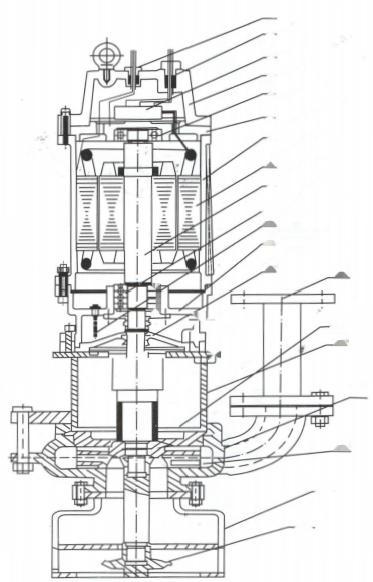

Product Structure Description

ZJQ and NSQ submersible slurry pumps/sand pumps consist of a motor and a pump, separated by an oil isolation chamber and mechanical seal components. They are electromechanical integrated products. The motor and pump share the same shaft (rotor), resulting in a short overall pump length and compact structure. Equipped with multiple protection devices, the pump operates safely and reliably.

Uses a Y-series national standard motor with F-class insulation, ensuring safe and reliable operation.

Uses a double-channel series seal with a new type of alloy material, featuring reliable sealing, wear resistance, and long service life.

The flow components use high-chromium slurry pumps, which are wear-resistant, high-performing, and have excellent flow performance. Their service life is 2-10 times longer than that of similar domestic pumps.

1. Signal Cable 11. Oil-Water Probe 2. Motor Wiring 12. Oil Chamber 3. Junction Box 13. Mechanical Seal 4. Motor Cover 14. Guard Plate 5. Bearing 15. Discharge Pipe 6. Upper Shaft Bracket 16. Bracket 7. Motor Housing 17. Pump Body 8. Stator 18. Impeller 9. Shaft (Rotor) 19. Bottom Base Filter 10. Bearing 20. Cutter Performance Parameter Table

Product Model Speed

(r/min)Flow Rate

(m³/h)Head

(m)Power

(KW)Diameter

(mm)40ZJQ/NSQ 8-12-2.2 1450 8 12 2.2 40 10-21-5.5 10 21 5.5 40 15-12-3 15 12 3 40 18-19-5.5 18 19 5.5 40 23-10-3 23 10 3 40 25-17-5.5 25 17 5.5 40 50NsQ 12-6-3 1450 12 6 3 50 20-20-4 20 20 4 50 25-15-4 25 15 4 50 25-30-7.5 25 30 7.5 50 30-16-5.5 30 16 5.5 50 35-6-4 35 6 4 50 45-14-5.5 45 14 5.5 50 65ZJQ/NSQ 25-15-4 1450 25 15 4 65 47-34-11 47 34 11 65 56-27-11 56 27 11 65 71-25-11 71 25 11 65 80ZJQ/NSQ 10-15-5.5 1450 10 15 5.5 80 30-30-7.5 30 30 7.5 80 45-15-5.5 45 15 5.5 80 70-20-7.5 70 20 7.5 80 Product Model Speed

(r/min)Flow Rate

(m³/h)Head

(m)Power

(KW)Diameter

(mm)80ZJQ/NSQ 70-35-15 1450 70 35 15 80 80-15-7.5 80 15 7.5 80 80-20-11 80 20 11 80 80-45-22 80 45 22 80 100-20-11 100 20 11 80 100-30-15 100 30 15 80 130-19-22 130 19 22 80 100NsQ 80-25-15 1450 80 25 15 100 100-12-7.5 100 12 7.5 100 100-20-15 100 20 15 100 100-30-18.5 100 30 18.5 100 120-18-15 120 18 15 100 120-35-22 120 35 22 100 150-25-22 150 25 22 100 150-38-30 150 38 30 100 160-80-90 160 80 90 100 180-22-22 180 22 22 100 200-35-37 200 35 37 100 150 NS 120-16-15 1450 120 16 15 150 150-22-18.5 150 22 18.5 150 150-35-22 150 35 22 150 Product Model Speed

(r/min)Flow rate

(m³/h)Head

(m)Power

(KW)Caliber

(mm)150 NSQ 180-25-22 1450 180 25 22 150 200-22-22 200 22 22 150 200-35-37 200 35 37 150 200-80-110 200 80 110 150 250-16-22 250 16 22 150 250-22-30 250 22 30 150 250-40-45 250 40 45 150 260-35-45 260 35 45 150 260-60-110 260 60 110 150 280-33-45 280 33 45 150 300-22-30 300 22 30 150 300-30-37 300 30 37 150 300-30-45 300 30 45 150 350-25-37 350 25 37 150 400-30-55 400 30 55 150 450-25-75 450 25 75 150 200 NsQ 300-25-37 1450 300 25 37 200 450-25-55 450 25 55 200 500-35-90 500 35 90 200 Features

1. Adopts advanced technology, strong sewage sludge removal capacity, no blockage, can effectively pass solid particles with a diameter of φ30~φ60 mm.

2. The tearing mechanism can tear and cut fibrous materials, and then smoothly discharge them, without the need to add a filter screen to the pump.

3. Reasonable design, small matching motor power, significant energy-saving effect.

4. Using the latest material mechanical seal, the pump can run safely and continuously.

5. Compact structure, easy to move, easy to install, can reduce engineering costs, no need to build a pump room.

6. It can be used in the full head range while ensuring that the motor is not overloaded.Installation System Instructions

1. Automatic Coupling Device System

Suitable for long-term fixed use occasions, with the advantages of quick installation, convenient inspection and maintenance. This system uses a special base, fixed at the bottom of the sewage pit, connected to the outlet pipe, and the matching support block is installed at the pool top. The guide rod connects the two, the water pump is connected to the specific bracket, goes down along the guide rod to the base, automatically couples and seals with it, and automatically falls off when lifted.

2. Mobile Installation System

It is supported by a bracket, and it can work after connecting the water outlet hose. This method is mainly used for emergency or maintenance construction needs.

Pump Usage and Precautions

1. Before using the pump, carefully check whether the cable is damaged, whether the fasteners are loose or fall off, and whether the pump is deformed or damaged during transportation, storage, and installation.

2. Use a 500V megohmmeter to measure the insulation resistance between the electric pump motor and the ground. The value should not be less than 2 megohms. Otherwise, the stator windings of the motor should be dried. The drying temperature should not exceed 120℃.

3. The installation of this series of pumps has two types: fixed and mobile. When using the fixed automatic installation, the chain should be put into the two lifting ring screws or lifting plates (deviating from the pump outlet, and the connecting line should be parallel to the pump outlet) to lift the electric pump up and down. Uniformly and slowly slide along the guide rail until it is automatically coupled. When using the mobile installation, first put on the hose, lift the electric pump up and down with the chain, and pay attention to not using the cable as a rope to avoid danger.

4. The rotation direction of the pump after being turned on is counterclockwise from the inlet. If the electric pump is reversed, just swap any two wires in the cable.

5. The ground wire of the electric pump casing must be strictly connected according to the relevant regulations. To ensure personal safety during use, it is strictly forbidden to install people in the water or move near the electric pump during operation to prevent electric shock accidents.

6. The electric pump must be equipped with a fully automatic water pump control cabinet under normal circumstances. Do not directly connect to the power grid or use a knife switch to connect the power supply to ensure the normal operation of the electric pump.

7. Do not run the electric pump in a low head state for a long time (the general working head should not be lower than 60% of the rated head). It is best to control it within the recommended working head range to prevent the electric pump from overloading and burning the motor.

8. Pumps without self-circulating cooling devices are strictly prohibited from running out of the water for a long time to prevent the electric pump from overheating and damage.

Maintenance

1. The electric pump should be managed and used by a designated person, and the insulation resistance between the electric pump winding and the casing should be checked regularly.

2. After each use, especially after using thicker and more viscous slurry, the electric pump should be placed in clean water and operated for several minutes to prevent sediment from remaining in the pump and ensure the cleanliness of the electric pump.

3. If the electric pump is not used for a long time, it should be taken out of the water and should not be soaked in water for a long time to reduce the chance of the motor stator winding getting damp and increase the service life of the electric pump.

4. Under normal conditions, after the pump is used for 300-500 hours, the oil in the oil chamber should be added or replaced (10-30# machine oil) to keep the mechanical seal in good lubrication condition and improve the service life of the mechanical seal.

5. After the electric pump is disassembled and repaired, the casing assembly must be checked with a 0.2MPa air tightness test to ensure the reliability of the motor seal.

6. The sealing ring between the impeller and the pump body has a sealing function. If the seal is damaged, it will directly affect the performance of the pump. It should be replaced if necessary.

Common malfunctions and troubleshooting methods

Malfunction Cause Troubleshooting method Insufficient flow

or no water1. Motor reversal

2. Impeller flow passage or pipeline blockage

3. The device head is too high, or the head of the selected pump is much lower than the actual requirement

4. Severe impeller wear

5. The liquid level is too low, causing the pump to suck in air

6. Check valve installed in reverse direction1. Correct motor direction

2. Remove debris from the impeller or pipeline. It is best to install a filter screen around the pump (but do not install a filter mesh at the pump inlet).

3. Try to reduce the device head (such as changing to a larger diameter pipe or smooth pipe, reducing the number of elbows, or increasing the radius of curvature of the elbows) or using a pump with a higher head.

4. Replace the impeller

5. Adjust the float switch position so that the lowest liquid level meets the installation requirements.

6. Correct the check valve direction.Cannot start 1. Phase missing

2. Impeller jammed

3. Winding joint or cable breakage

4. Stator winding burnt out

5. Control electrical malfunction

6. Power voltage too low1. Check the wiring and eliminate the phase missing problem

2. Remove debris; it is best to install a filter screen around the pump (but do not install a filter mesh at the pump inlet).

3. Check with an ohmmeter and repair

4. Repair, replace the winding or stator

5. Check the control cabinet, repair or replace electrical components

6. Address the power voltage issueStator burnt out 1. Without protective control electrics; operation or start-up under phase-missing conditions; impeller jammed or detached; excessive medium concentration; blocked cooling system

2. Seal damage, motor water ingress

3. Loose fasteners causing motor water ingress

4. Motor running above water level for extended periodsBefore using the motor after repair, you must:

1. Configure protective control electrics and: check the wiring, eliminate phase-missing faults; remove dirt, tighten impeller fastening screws and stainless steel spring washers; dilute the medium with water; flush and unclog the cooling system

2. Replace mechanical seal or "O"-ring

3. Tighten all fasteners

4. Ensure the minimum liquid level does not fall below the specifications in the installation drawingExcessive current 1. Higher density or viscosity of the pumped liquid

2. The selected pump's head is much higher than the actual requirement, or the operating conditions have changed, and the device's head has been significantly reduced, causing the pump to operate beyond the recommended flow rate.

3. Bearing damage

4. Debris trapped between the impeller and the pump body (e.g., at the mouth ring)

5. Power voltage too low1. Change the density or viscosity of the pumped liquid

2. Close the outlet valve to reduce the flow rate, or trim the impeller, or replace a pump with a lower head

3. Replace the bearing

4. Remove debris

5. Address the power voltage issueLarge vibration and noise 1. The selected pump's head is much higher than the actual requirement, or the operating conditions have changed, and the device's head has been significantly reduced, causing the pump to operate beyond the recommended flow rate.

2. The liquid level is too low, causing the pump to suck in air

3. Improper piping arrangement, such as a valve installed close to the pump outlet and the valve is closed slightly, an elbow installed close to the pump outlet, or the diameter of the discharge pipe close to the pump outlet suddenly shrinks. The diameter of the suction pipe of the installed pump is smaller than the inlet diameter of the suction elbow.

4. Bearing lacks grease or is damaged

5. Debris is stuck between the impeller and the pump body (accompanied by increased current)1. Close the outlet valve to reduce the flow rate, or trim the impeller, or replace a pump with a lower head

2. Adjust the float switch position so that the minimum liquid level meets the requirements of the installation dimensions.

3. Identify and resolve the specific problems with the piping setup.

4. Lubricate or replace the bearings.

5. Remove any foreign objects.

Product System

The company's industrial pump production base focuses on meeting the needs of various industrial scenarios. We are committed to creating products such as slurry pumps, desulfurization pumps, dredging pumps, submersible pumps, and chemical pumps. From the demand for high wear-resistant slurry pumps in large-scale mining, to the dependence on high-efficiency desulfurization pumps in power plant desulfurization, to the strict requirements for high corrosion-resistant chemical pumps in fine chemical processes, we can provide high-performance products that are suitable for all. These pumps are widely used in industries such as mining, power plant desulfurization, river sand mining, metallurgy and steel, chemical industry, etc.

The valve production base covers various categories such as ball valves, gate valves, butterfly valves, etc. With excellent quality and reliable performance, it is widely used in the fields of oil and gas transmission pipelines, urban water supply and drainage systems, etc., to ensure the safe and stable operation of various fluid transmission systems.

Contact Us

Keywords: